Early in our history the three most transformational inventions are widely accepted as the wheel, the lever and the inclined plane. While the wheel is more popularly well known, the inclined plane is not so much. It lacked the recognition or a good publicist. Even less so is the fact that the screw is actually a much more useful version of the inclined plane. So are propellers and electric fans, the cork screw, rack and pinion gear system, and of course the spiral lanes in multi-level car parks, etc.

Why the nerd talk? Well, it is to recognize the contribution of the inclined plane and its derivative - the humble screw and the driver that makes a lot of wood working projects possible. Wood is put together using just three major means - glue, nail and screws (including knock-down furniture). I favor glue but if I must use any hardware at all, it will have to be screws or threaded bolts.

Understanding why it works is understanding the science of the inclined plane.

Below is the anatomy of the screw. The thread of a screw, unwound, is an inclined plane. I made the illustration below to show science behind the mechanical advantage that the screw offers.

The early screws were flat heads with single notches or slots. Flat head screw drivers had to concurrently come along, just as hammers were to nails.

Flat heads ruled for a very long time, like the dinosaurs did. And dinosaurs they've become. Then came the cross-slotted Philips screws and the Philips screw drivers. Today ...

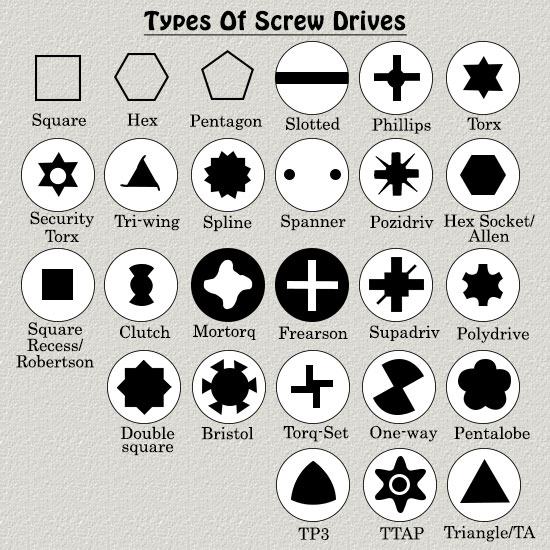

More and more we see specialty screws that require dedicated screw driver heads. Manufacturers therefore had to come up with a more practical solution to deal with the varieties of screw heads with a single handle with interchangeable driver bits.

| And the handle can bend as shown for more leverage. |

| And furthermore, a rod inserted through a hole increases the torque power even more. |

And speaking of torque power, the portable electric drill/driver came along. Then came a variety of quick connect/disconnect bit holders, stemmed to fit standard chucks on all drill/drivers. See two clever examples below.

Then came along another innovation in quick connect/disconnect designs from the maker of Centrotec technology. See description below. The new handle that is reasonably priced at $24 is a cut above all others. The bad news is that it will only take Centrotec bits.

But, with an adapter, universal bits of all varieties can be used. However, the adapter can cost another $26-29. However, it is worth an investment if you already have a bunch of universal bits. Then you will have a wobble-free hand held screw driver with an almost infinite choices of bits, including sockets for driving small bolts.

| By the way, a shorter configuration means more comfort and "sure-footed" driver for added confidence in driving screws. |

Here is the dream screw driver set to last a life time.