There is no good reference record as to exactly when or where this type of saw was recorded to have been used for the first time. Apparently, Roman carpenters may have first begun fashioning saws with thin blades on bowed frames to make curve cuts. It is also known by different names. It's a bow saw (for one obvious reason), a turning saw or a curving saw. It is known under the umbrella of frame saws. A bow saw is likely the one made with a metal frame known to have started in Sweden, where the term "bow" associated with saws was first used and during that time folks from outside that country simply called them "Swede saws" in the early 1900s. It was a high tech tool of its time.

First two photos below are traditional designs made from solid hard wood frames. I wanted to make one although I prefer straight lines mostly for my projects. I seldom use curved shapes which is why I do not own a band saw (aside from the fact that I really don't have any more space to put one in my small workshop). Most of the curve cuts I do are with a power jig saw or bench top scroll saw and a manual coping saw for thin work pieces. So, why make one? An old world tool at that? It was a challenge and a creative outlet in the midst of the Corona virus lock down.

I wanted to improve on the design with a different construction method and look.

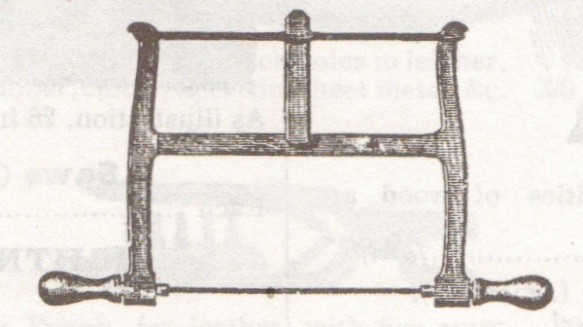

Parts of a fully assembled saw are labeled below. The saw can be disassembled into all its basic parts and re-assembled in very little time.

First, I cut strips of 1/2 inch Baltic plywood.

I ripped and sliced pieces of Padauk to 1/4 inch thickness. Padauk is a dense and heavy hardwood native to Southeast Asia and distinctly reddish in color. The Philippine Padauk is known as Narra, which is the country's national tree. A while back I had purchased a 1 X 4 X 48 inch board, among several other pieces of hardwood from a supplier that was going out of business. Even at a close-out sale it was still quite pricey so I waited and waited for the right project. Until now.

A solid Padauk would be quite heavy for a hand tool the size of this saw. Laminating it over a very stable but lighter Baltic plywood not only makes the overall weight lighter, it will be much more rigid where the goal was to get maximum resistance to bending such as cast metal would.

Speaking of hand tools, I recently added for the first time a Japanese hand plane (left, photo below next to the western one which I made a while back ). Like the Japanese saw, which is what I use exclusively, this operates on the pull (starting away from and towards the user's body with a pulling action). It was not that difficult to get used to and it does seem a tad easier to control.

Photo below does show how the laminated work pieces look.

Below, marking the mortises, later cut with drill and chisel, for the ends of the stretcher to fit into.

For good measure I created a 1/4 inch groove on both arms where I glued 1/4/ X 1/4 solid walnut to reinforce the entire length.

The handle and the toe were from one laminated piece - this time using a 3/4 inch plywood clad with the Padauk.

As you can tell I need to practice for a bit longer to achieve more accurate and smoother cuts (below).

I have an interesting footnote story on the Padauk. As mentioned earlier, it is known in the Philippines as Narra. Species vary from region to region in the Far East in redness. The one I used here is likely from the region in or around Myanmar - which is intensely red, other species could be much darker red or lighter with streaks of whitish yellow or brown.

Many years ago while working in the Philippines, my family and I moved to the southern island of Mindanao and lived in the city of Davao, for a one-year stint. Our second son was born there. Just outside the city was a national penitentiary. Inmates there had options to work on trade crafts to make use of their time (many with very long prison sentences). One of those trade crafts was woodworking. The finished products were sold to the public at a store outside. One day my wife and I went and bought two pieces of pedestal corner tables. Years after that we immigrated to the U.S. We did sell a lot of our household stuff but the few that remained, which included the two tables, stayed at my in-laws home . Years later on one of our visits back to the Philippines I decided to have the two pieces dis-assembled and brought them back with our luggage. Fast forward to another two decades and here they are, still in their dis-assembled state, but in good shape despite the garage environment where they sat and sat.

After this saw project, I remembered the pieces and realized they were made out of Narra (Padauk). The larger piece is a 21 inch diameter solid (not from joined pieces) wood.

|

| Carving solid pieces of hardwood must have taken a long time. The inmates may not have had the sophisticated modern tools but time - they had copious amounts of it. |

|

| The bottom side clearly shows they were solid pieces (not glued boards), so we can only imagine how huge the tree that they came from. |

|

| The Padauk piece I bought against the old table. |

|

| The pedestals though dissimilar in design were also from solid pieces |

I now aim to make this a project very soon. We bought these in 1977. It's about time I do something about it. Of course, back then I had no idea I will take up woodworking as a hobby when we came here. Now, I realized too that the inmates, while very skilled, did not have access to really good tools and fastening material, including quality glue and screws. So they used nails to fasten everything.

I need to preserve these pieces now that I just learned that the huge Padauk trees that grew to as much as 7 feet in girth are rare. Narra is not quite in the endangered list but it is under the category of vulnerable.