As hobbyist workshops go, my workshop can only be described as adequate, at best, petite by some standards. Though I'll have to say, more than petite projects have come out of it over the years. The previous owners of the house (built in 1990, we purchased it in 2005) had this built in addition to but separate from the three-car garage at the back of the house. It was made as a garden/yard tool room at the back of the house adjacent to the garage. It is only 205 sq. ft, or 18.5 sq. meters for my metric readers. It's 1845 cubic feet, or 53 cu. meters. (This matters, of course, for cooling or heating calculations).

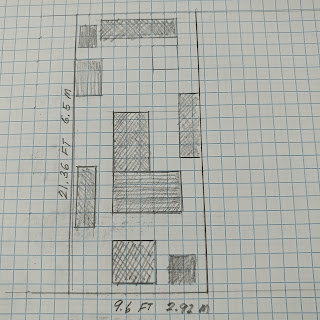

Below is almost a drawn-to-scale layout where the blank grids are the areas I can move about, while the shaded rectangles are the tools and other space occupiers that are excluded from foot traffic. And it is definitely a one-person workshop.

Part 1 is the Workbench

If the table saw is the mouth, doing all the chewing and cutting from big work pieces to small pieces, the workbench is the stomach, where all the digesting takes place, glue ups and assembly, because this is where the workpieces then become useful projects. At least, that is the ultimate plan. Now, woodworking is possible without the table saw but clearly a non-starter without the workbench. It can be as low as a foot or less above the floor, as in ancient-style Japanese woodworking (still practiced today by Japanese purists) or 28 inches or higher in modern workshops.

Years ago I purchased a baker's table made of maple. Its original mission, I was told, was to be at the bakery. With a portable circular saw, I ripped it lengthwise into three sections: a wider piece and two narrower pieces. I turned it into a European-style workbench which is defined mainly by a center channel somewhere in between what essentially looks like two bench tops. The idea is for the channel to serve as repository for wastes like shavings, chips, saw dusts or as a space to park hand tools like chisels, hand planes, etc. while not in use but easily within reach by the woodworker.

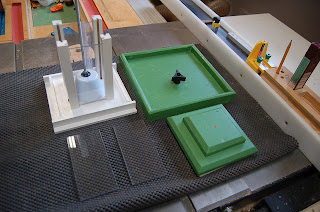

It is about 28 inches tall, 29 X 53 inches overall at the top. I positioned it so its one end butts directly into the forward end of the table saw. The narrow painted red channels will accommodate the runners for a table saw sled to run into (if used). There are T-tracks (blue) for T clamps for various clamping locations on the table top.

It is about 28 inches tall, 29 X 53 inches overall at the top. I positioned it so its one end butts directly into the forward end of the table saw. The narrow painted red channels will accommodate the runners for a table saw sled to run into (if used). There are T-tracks (blue) for T clamps for various clamping locations on the table top.A section of the center piece from the original top serves as a temporary extension that can slide in and out, guided by drawer-style runners on the side. Once clamped, even temporarily, it is quite a robust extension.

Visible below is the rowing machine runner where the tray can slide to and fro. It can also be temporarily set aside if needed.

Assembling is the penultimate to a hopefully rewarding denouement for any woodworking project.

This bench is also a great platform for several bench top power tools - miter saw, scroll saw, sander, planer, etc. which from time were shown in my other earlier blogs.